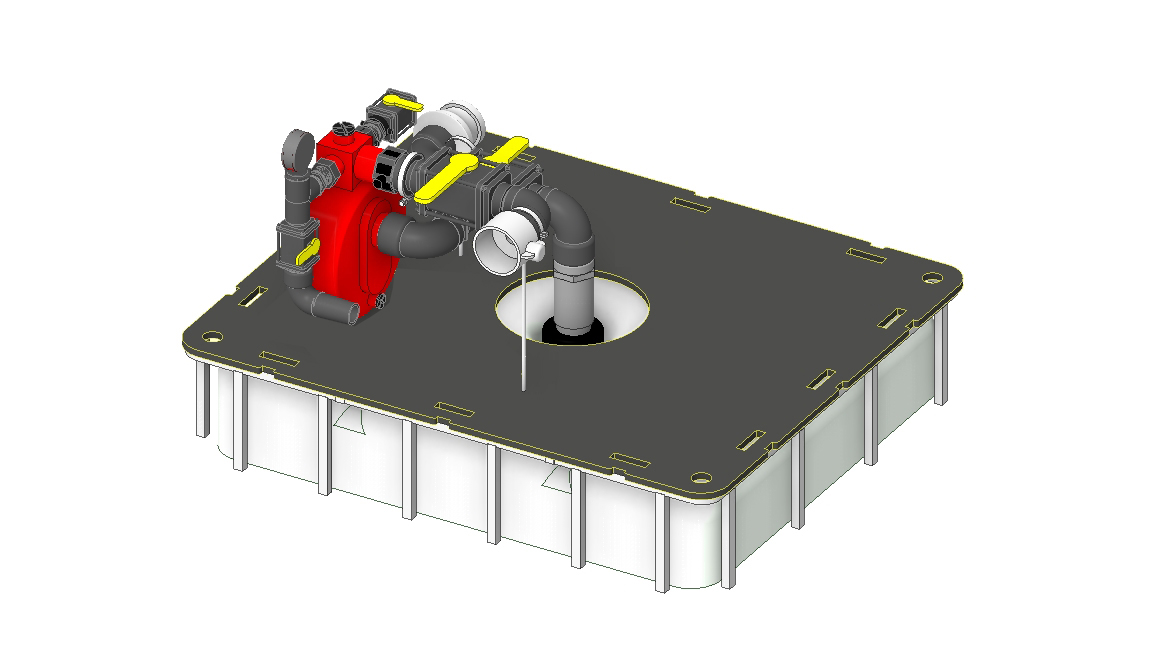

IBC Guardian Tote Topper (Top for an IBC) and Pump System

Developed from our experience within the fire fighting industry our IBC Guardian Tote Topper and Pump System provides a highly mobile and effective solution for a wide range of applications, including but not limited to industrial and agricultural use [see example uses]. We designed a robust top for an IBC which offers convenience, flexibility, and performance, making it ideal for rapid deployment in various environments.

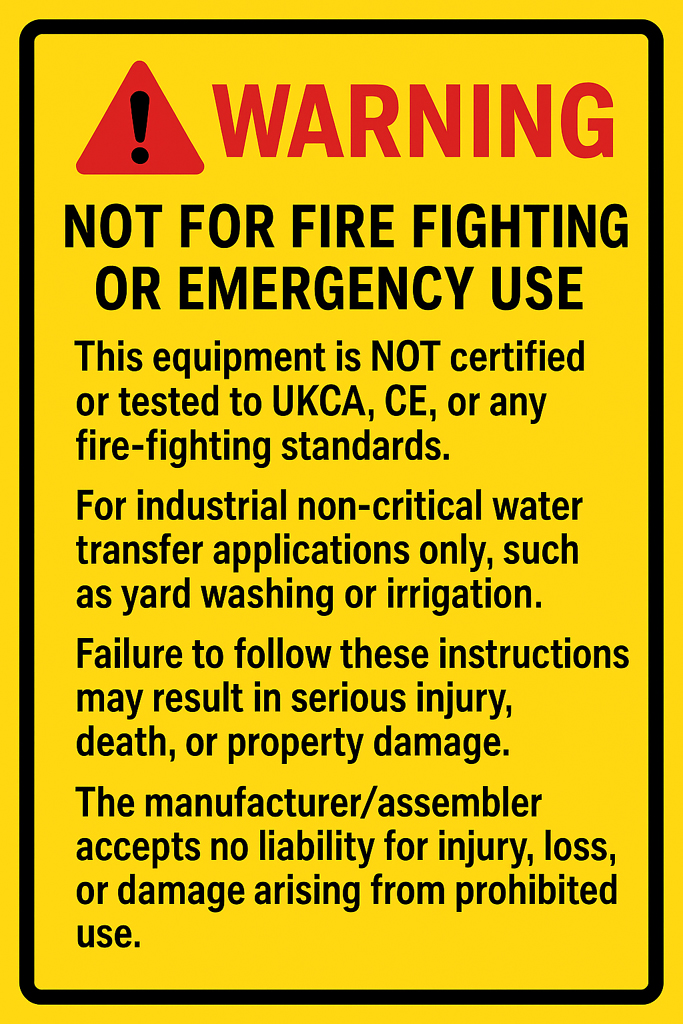

The unit is not limited to a single role and can be adapted for many different uses across multiple applications. Whilst the pump we use was designed for fire fighting, it is not certified for emergency or fire-fighting use (see FAQ’s for more details).

* IBC Guardian Tote Topper and Pump available separately or as a complete system with or without an IBC

Key Features & Benefits

1. Large 1000L Water Capacity

IBC’s provide a substantial water reserve to support sustained delivery. More details ….

Allows for extended operation before a refill becomes necessary.

Need more volume? You can easily link multiple IBCs without needing to reconfigure the setup.

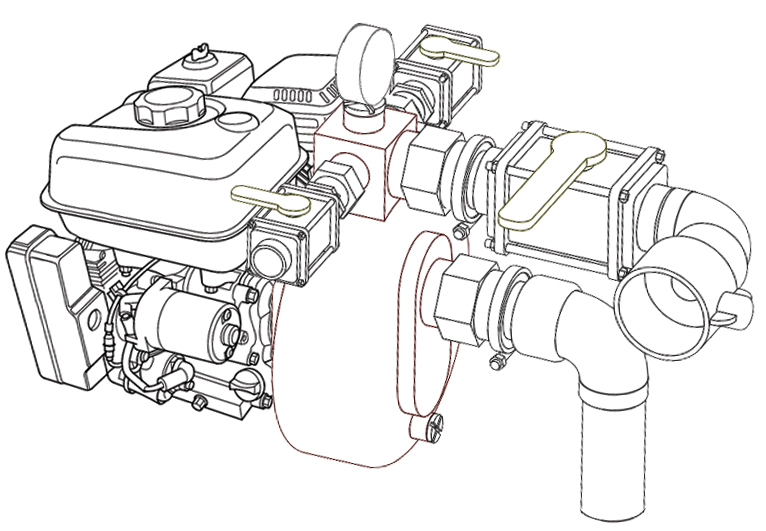

2. Powerful 6.5HP Petrol Engine & Pump

Key-start ignition (with Recoil Backup) ensures fast, hassle-free activation.

Multiple outlet configurations

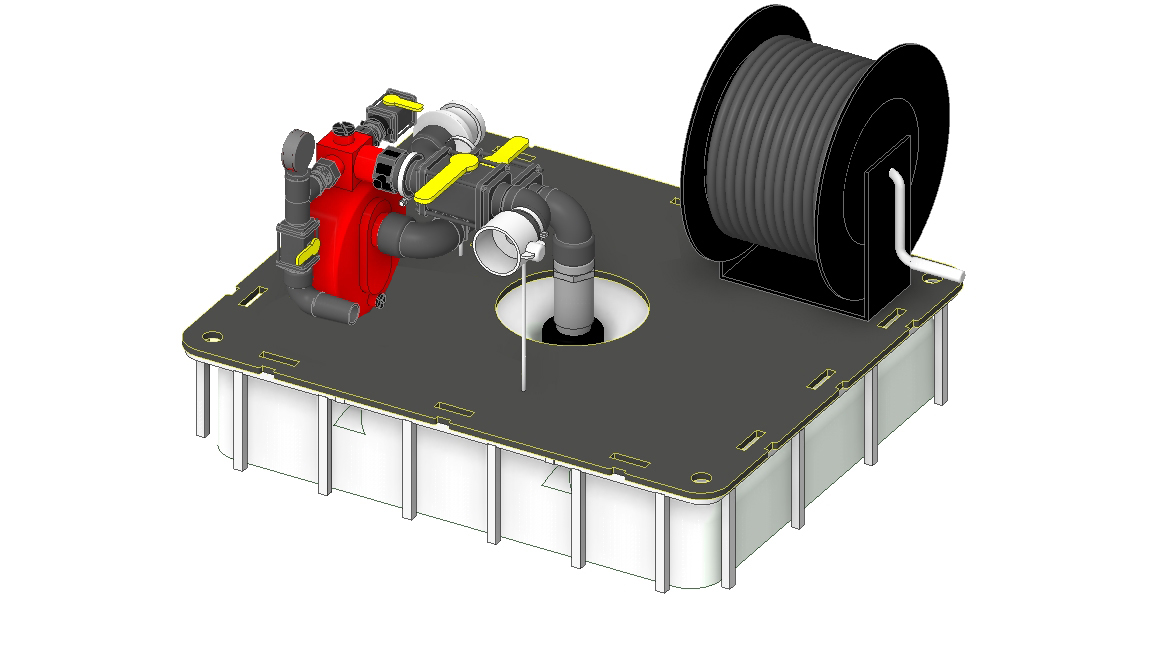

3. Integrated Hose Reel (Option)

Rapid deployment.

The flexible system allows for precise focus of water stream.

Variable flow and pattern control ensure adaptability for different applications.

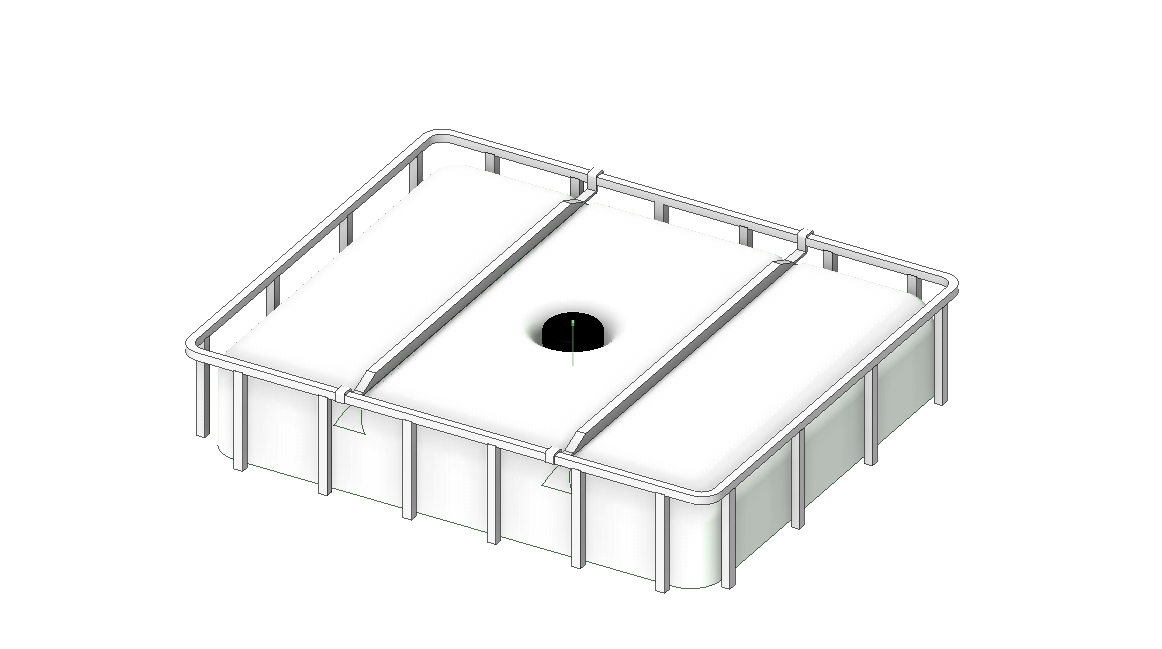

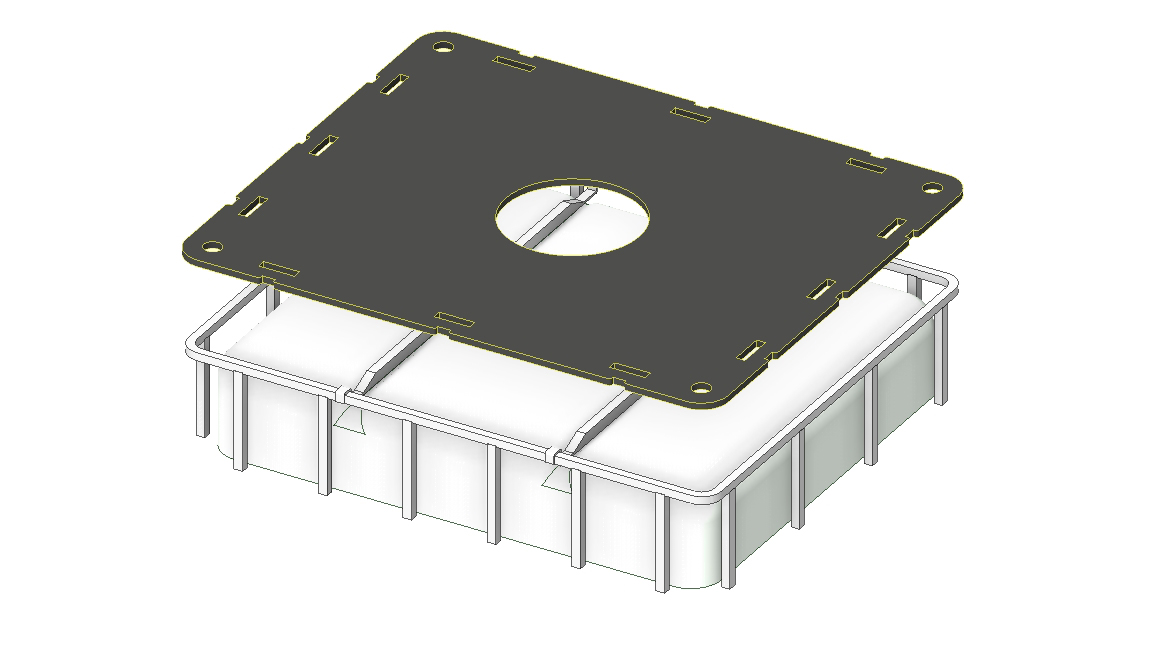

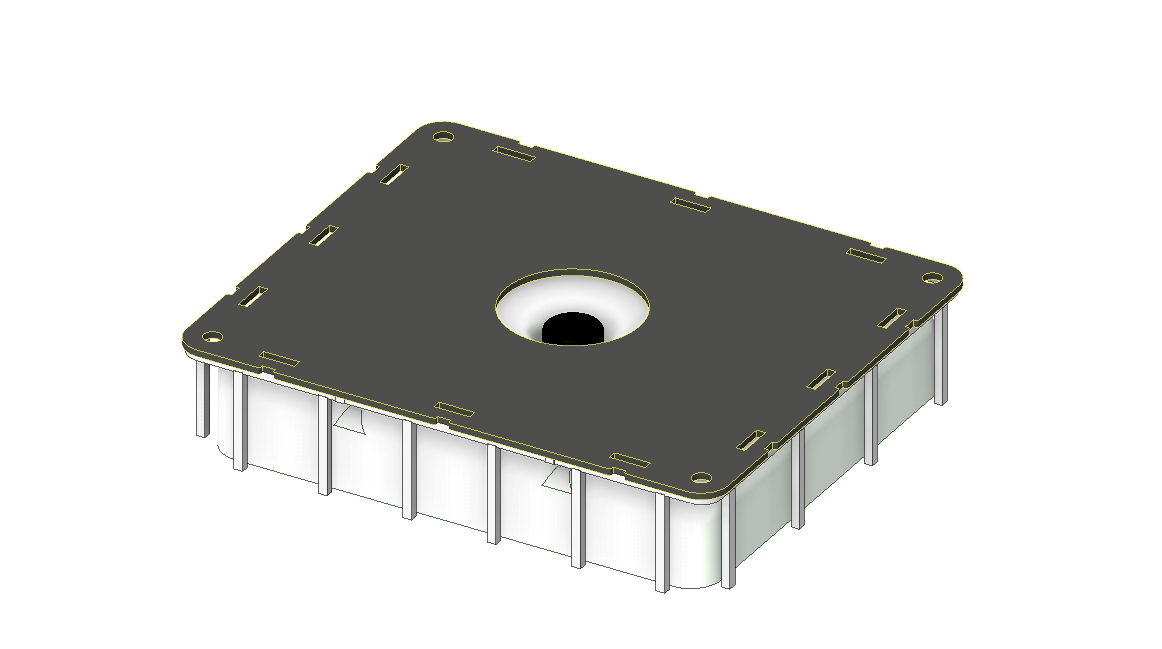

4. Robust Polyethylene Top (more info)

Offers a secure platform to mount pumps and hose reels etc.

Made from tough, weather-resistant polypropylene (made to BS EN 12573 standard).

5. Ultimate Mobility & Deployment

Forklift / Pallet Truck Compatible: Easily move it around for use in various location.

Pickup Truck Friendly: Fits conveniently in most pickup beds for mobile applications ideally with a 500L IBC Tote due to vehicle weight limitations.

Perfect for a Range of Applications

Cleaning: Ideal for factories, warehouses, and construction sites requiring a large water supply and reasonable pressure for sluicing.

Dust Suppression: Great for construction or demolition sites for dust supression

Irrigation: Offers 1000L with optional deliveries for different applications

Firefighting: not certified for emergency or fire-fighting use

Why Choose the IBC Guardian Pump System?

Offers a cost-effective solution.

Easy to operate and quick to deploy using a forklift or pallet truck

Designed for multiple applications

Offers variable hose outputs

Option for hydrant input

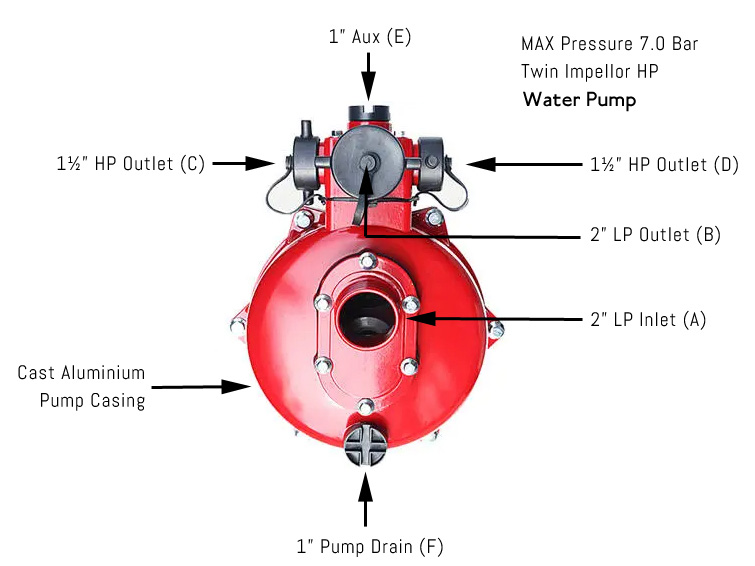

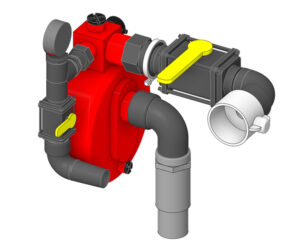

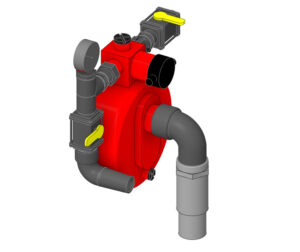

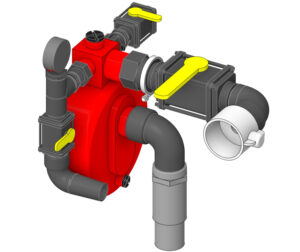

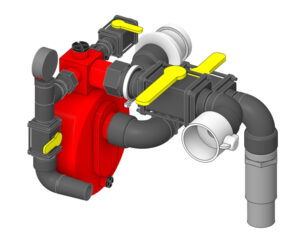

Most pumps include one inlet and one outlet with no option for switching between sources. Our pump system offers multiple outlet choices and the ability to switch from tank supply to hydrant or another source. It works much like a fire engine system but on a smaller and more practical scale.

Equip your IBC tote with the IBC Guardian Tote Topper and Pump System for a 1000L delivery solution. Enjoy the convenience and efficiency of a fully integrated pumping and delivery setup.

Designed by us to perfectly fit a standard IBC (Intermediate Bulk Container). The IBC Guardian platform is constructed from impact-resistant, textured polypropylene, (more info) meeting the BS EN 12573 standard. As a result, it can be configured to accommodate a wide range of applications with ease.

( IBC NOT INCLUDED BUT CAN BE SUPPLIED )

The platform is designed to mount directly onto a standard IBC, using the existing frame for support. This integration reduces the need for heavier materials and enables the use of thinner polypropylene without losing strength.

As a result, the platform securely holds a pump and engine, a hose reel with hose, and other required components. These parts can be arranged to suit any of the available customer configurations.

Features

- Flows up to 300LPM at 6-7bar (Max)

- Reliable 6.5HP Petrol Engine

- Electric start with recoil backup

- Displacement 196cc

- Constant Power 3.6Kw at 3600 r.p.m

- 3.6L Fuel Tank Capacity

- Twin impeller

Applications/Solutions *

- Irrigation

- Sluicing

- Cleaning

- Dust Supression

- Agricultural use

* not certified for emergency or fire-fighting use

Flexibility

One of the main advantages of this system is its outstanding transport versatility. IBCs are widely used across many industries and are naturally compatible with forklift handling. This built-in mobility makes them perfect for industrial sites or any location with a forklift or tractor available.

They can also be stored conveniently in designated on-site areas for easy access when required.

The IBC Guardian pump system can include a customizable manifold for maximum flexibility in different operations. Depending on the setup, it can support either a hose reel or a layflat hose.

The manifold is built from readily available polymer components rated to handle at least 7.0 bar pressure. These parts are designed to match or exceed the pump’s maximum output capacity.

The manifold provides functionality comparable to larger pump systems or vehicle-mounted units. It achieves this performance in a much more compact and mobile design.

Available System Options:

30m x 3/4″ Hose Reel (rated @ 20 bar max)

2½” Instantaneous Layflat Hose

Hydrant or Direct Supply

Overheat Protection

The IBC Guardian pump includes a standard manual re-circulation circuit, providing extra protection and improved efficiency during operation.

Small pump systems often overheat when water flow is restricted, such as with a closed branch outlet. To prevent this, a manually operated return valve redirects flow back into the tank.

This design conserves water and keeps the pump cool during idle or low-flow periods.

High Quality Components

We use high quality Banjo Ball Valves which offer reliability with smooth operation

- 7-10 Bar maximum pressure at 21°C (Max pump pressure 7.0bar)

- FKM (viton type) seals

- Precision moulded polypropylene reinforced with fibreglass

- Self-aligning ball moves freely against the PTFE seals

- Ball is diamond turned to make it spherically perfect to provide precise contact between ball and seals

- Stainless steel bolts

- The valve opens or closes with very little pressure on the handle

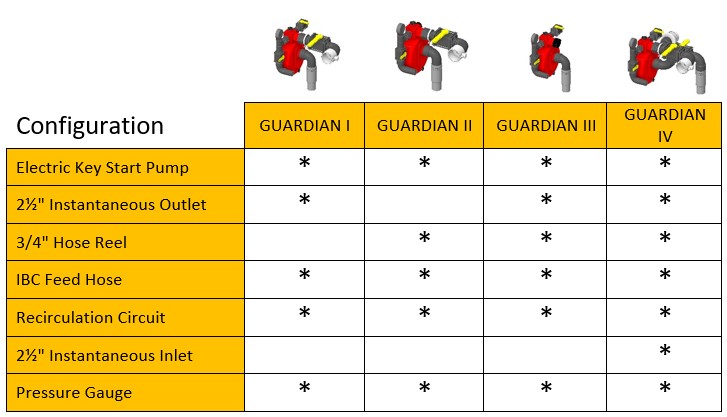

IBC Guardian Pump Options

Select from the pump options below to view configuration and request more information